-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

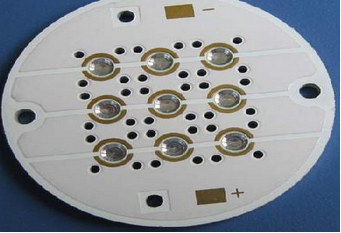

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

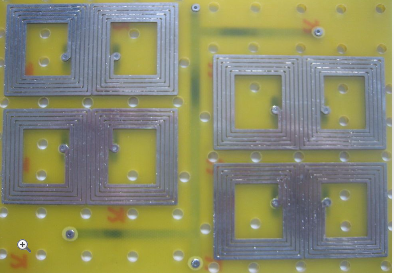

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

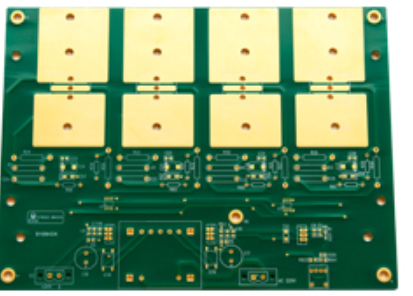

Heavy Copper PCB Design Delivering Increased Power Handling Capabilities And Enhanced Durability For Mission Critical Applications

In the rapidly evolving landscape of electronics, where demands for higher power, greater reliability, and uncompromising performance are paramount, a specialized technology has emerged as a cornerstone for mission-critical applications: the Heavy Copper Printed Circuit Board (PCB). Unlike standard PCBs, which typically feature copper weights of 1 oz/ft² to 2 oz/ft², Heavy Copper PCBs are defined by copper layers that start at 3 oz/ft² and can extend dramatically to 20 oz/ft² or more. This fundamental design choice is not merely an incremental improvement but a transformative approach, delivering significantly increased power handling capabilities and enhanced durability. From aerospace and defense systems to industrial power converters, automotive control units, and renewable energy infrastructure, these robust boards are engineered to thrive in harsh environments where failure is not an option. This article delves into the intricacies of Heavy Copper PCB design, exploring how it meets the rigorous demands of applications where performance, safety, and longevity are critical.

The Engineering Foundation: Defining Heavy Copper and Its Core Advantages

At its heart, a Heavy Copper PCB is characterized by the substantial thickness of its copper traces, planes, and plated through-holes. This increased copper mass is achieved through specialized plating and etching processes that can build up copper in desired areas far beyond standard manufacturing limits. The primary advantage of this added bulk is a dramatic reduction in electrical resistance. According to fundamental principles, the resistance of a conductor is inversely proportional to its cross-sectional area. By significantly increasing the copper's thickness, the PCB can carry much higher currents without excessive heating, voltage drop, or energy loss.

This capability directly translates to superior power handling. A standard PCB trace might overheat and fail under high current loads, but a Heavy Copper trace of equivalent width can safely sustain that load, enabling the design of more compact and powerful circuits. Furthermore, the enhanced thermal performance is twofold: the thicker copper acts as an excellent heat spreader, dissipating thermal energy away from hot components like power transistors or regulators more efficiently across the board and towards heatsinks. This intrinsic thermal management reduces hotspots, lowers overall operating temperatures, and significantly boosts the long-term reliability of all onboard components.

Structural Integrity and Enhanced Durability for Harsh Environments

Beyond electrical performance, the mechanical robustness of Heavy Copper PCBs is a key driver for their use in mission-critical systems. The thick copper layers add substantial structural integrity to the board itself. This makes the PCB more resistant to mechanical stresses such as vibration, shock, and flexing, which are common in automotive, aerospace, and industrial settings. Connector points and plated through-holes, which are often points of failure, are immensely strengthened. The heavy plating in these vias reduces the risk of cracking during thermal cycling, as the copper and the surrounding substrate expand and contract at different rates.

This leads directly to the second major durability benefit: exceptional performance under extreme thermal cycling. Mission-critical applications, from down-hole drilling equipment to avionics, experience wide temperature fluctuations. The robust construction of Heavy Copper PCBs, with its strong plated vias and thick planes, withstands these repeated thermal stresses far better than standard boards. The result is a dramatically extended product lifespan and reduced probability of in-field failure. Additionally, the ability to integrate high-current components and thermal management features like embedded heatsinks directly into the board structure allows for simpler, more reliable system designs with fewer points of potential mechanical failure.

Design Innovations and Integration Capabilities

The design philosophy for Heavy Copper PCBs opens up unique possibilities for circuit architects. One of the most powerful is the ability to integrate what would traditionally be separate, bulky components directly onto the PCB substrate. For instance, high-power bus bars, which are typically external metal bars for current distribution, can be fabricated as part of the copper layers. Similarly, planar transformers and high-current inductors can be designed using the thick copper windings embedded within the board stack-up. This level of integration minimizes interconnections, reduces parasitic inductance, improves overall efficiency, and leads to a more compact and reliable final assembly.

Furthermore, designers can leverage the technology to create sophisticated, multi-purpose board features. A single heavy copper plane can simultaneously function as a high-current path, an electromagnetic interference (EMI) shield, and a highly efficient thermal conduit to an external chassis or heatsink. This multifunctional approach simplifies the overall system design, reduces part count, and enhances performance. The design process, however, requires specialized expertise in DFM (Design for Manufacturability) to account for the etching and plating challenges associated with extreme copper weights, ensuring the final product is both functional and producible.

Applications in Mission-Critical Sectors

The unique benefits of Heavy Copper PCB design make it indispensable across a spectrum of high-stakes industries. In the aerospace and defense sector, these boards are found in flight control systems, radar and communication equipment, and weapon systems, where they must handle high power pulses and survive extreme G-forces, vibration, and temperature variations. Similarly, the automotive industry, especially in electric and hybrid vehicles, relies on them for battery management systems (BMS), motor controllers, and DC-DC converters, where they manage hundreds of amps reliably in confined, under-hood environments.

Industrial applications form another major domain. Power converters, inverters, motor drives, and welding equipment all utilize Heavy Copper PCBs to control and distribute large amounts of energy with high efficiency and ruggedness. In the energy sector, both traditional power grid monitoring systems and modern renewable energy installations like solar panel inverters and wind turbine controls depend on their durability and high-current capacity. In each of these fields, the consequence of a PCB failure can range from costly downtime to catastrophic system failure, justifying the investment in the superior resilience offered by Heavy Copper technology.

Manufacturing Considerations and Future Outlook

Producing Heavy Copper PCBs requires advanced manufacturing techniques that go beyond standard PCB fabrication. Specialized plating baths and processes are needed to achieve uniform, void-free copper deposition in high aspect-ratio holes and on trace sidewalls. Etching such thick copper also presents challenges, requiring careful control to achieve fine feature definitions without undercutting. Manufacturers must employ robust quality control, including automated optical inspection (AOI) and meticulous electrical testing, to ensure the integrity of every high-current path.

Looking ahead, the trend toward electrification, higher power density, and more demanding operational environments ensures that the importance of Heavy Copper PCB technology will only grow. Innovations are likely to focus on combining heavy copper with other advanced technologies, such as embedded die, active cooling channels, or materials with higher thermal conductivity. As the Internet of Things (IoT) expands into industrial and critical infrastructure, the demand for reliable, high-power edge devices will further cement the role of Heavy Copper PCBs as a fundamental enabling technology, delivering the increased power handling and enhanced durability that our most vital systems depend on.

REPORT