-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

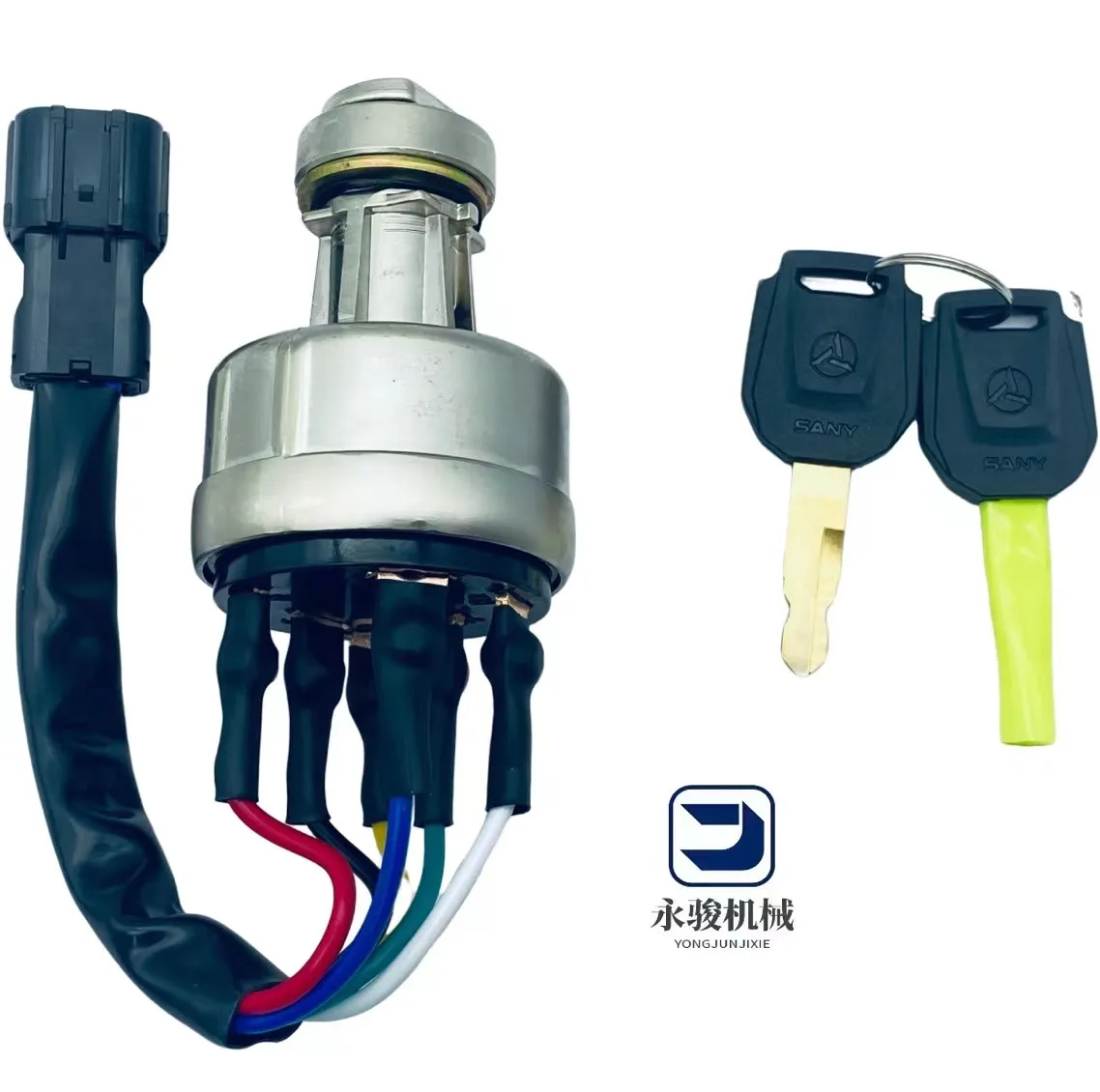

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Engineering & Construction Machinery

In the world of heavy machinery, where equipment represents a significant capital investment and operates in often challenging environments, security is not a luxury—it is an absolute necessity. Theft and unauthorized access can lead to devastating financial losses and dangerous operational hazards. It is within this critical context that the Excavator Door Lock Series emerges as a premier security solution. Engineered specifically for the rigors of industrial use, this series offers robust protection through advanced locking mechanisms and superior durability, providing peace of mind for owners and operators of excavators, bulldozers, and other vital machinery. This article delves into the features that make this product line an indispensable asset for safeguarding valuable equipment.

Advanced Locking Mechanisms for Uncompromising Security

The core of the Excavator Door Lock Series lies in its sophisticated locking technology. Moving beyond simple key locks, these systems often incorporate high-security cylinders that are highly resistant to picking, drilling, and other forced-entry techniques. This level of complexity ensures that only authorized personnel can gain access to the machinery's cab and controls, effectively deterring potential thieves and vandals.

Furthermore, many models within the series are equipped with integrated electronic components. These can include keypad entry systems, RFID card readers, or even biometric scanners, offering a seamless and keyless access experience. This multi-layered approach to security means that even if one layer is compromised, others remain active, creating a formidable barrier against unauthorized entry and protecting the substantial investment embodied by the heavy machinery.

Superior Durability for Harsh Operating Conditions

Heavy machinery operates in some of the most demanding conditions imaginable, from dusty construction sites to freezing cold mines. The Excavator Door Lock Series is built to withstand these extremes. The locks are constructed from high-grade materials such as hardened steel and corrosion-resistant alloys, ensuring they do not become the weak link in the machine's armor.

The design also incorporates robust sealing to protect the internal mechanisms from contaminants like dirt, mud, water, and debris. This attention to environmental resilience guarantees that the lock will function reliably day after day, regardless of weather or worksite conditions. This exceptional durability translates directly into long-term value, reducing maintenance needs and preventing costly security failures that could lead to equipment theft or tampering.

Engineered Integration and User-Friendly Design

A significant advantage of this series is that it is not a generic afterthought; it is precision-engineered for specific makes and models of excavators and other heavy machinery. This ensures a perfect fit and seamless integration with the existing door structure, maintaining the integrity of the machine's design without requiring extensive modifications.

Despite its high-security features, the lock system is designed with the operator in mind. The actuation is smooth and reliable, preventing jamming and ensuring easy access for authorized users. This focus on ergonomics and usability means that security does not come at the expense of operational efficiency, fostering greater acceptance and consistent use among equipment operators, which is crucial for maintaining a secure environment.

Understanding the Vital Role of Hydraulic Pumps in Excavator Function

Hydraulic pump: the heart of the system that converts mechanical energy (typically from the excavator engine) into hydraulic energy. This is done by creating a low volume, high-pressure hydraulic flow by displacing fluid.

The hydraulic pump then sends this high-pressure fluid to the hydraulic actuators — cylinders and motors — that move the excavator arm, bucket, and other work tools.

Fluid Distribution

Power generation is not just pumping the energy, the pump is also the controlling device. The distribution controls hydraulic flow so that only the amount needed reaches the correct actuator at the right time, which allows a user to perform complex motions with accuracy.

This level of control allows for both gentle operations (installing pipes or \\"slinging\\" a soft payload/object), and brutish operations (excavating into hard soil).

System Efficiency

The efficiency of the excavator has a considerable influence on the productivity and fuel consumption of the pump, Cost-effective operation will be possible only if there is a proper selection of pump and suitable maintenance will help reduce energy loss.

Modern pump technologies take this efficiency even higher with variable displacement pumps that waste little to no energy by matching the amount of output to the work performed.

From Tiny Movements to Massive Lifts Hydraulic Pumps in Excavators

Hydraulic pumps – Hydraulic pumps are the very power-translating element of an excavator which translate engine power into a set hydraulic pressure value. The hydraulic cylinders that drive the arm, bucket, or digest each actuates with precision when pressurized. It enables gentle demolition work with very minimum movements of a few microns both within the frame of the frame can be slight adjustments in pressure.

Amplified Force

All of that makes these systems a beautiful pascalian experiment. The hydraulic system does this in a way, through a mechanism, so that the low force that the pump produces is enhanced, as it is the boom that can hold such massive weights after all. That is what gives the big machines the advantage to deftly move tons of earth and other materials.

Efficiency and Control

It has been shown that a hydraulic system is more efficent system compared to the other forms of power transmission. These too offer a smooth, controlled motion, and much faster response to changing loads, to which a mechanical linkage would be upset by extreme masses or sudden changes in the load.

Loucks: The hydraulic pumps are driven off the engine but the fluid dynamics and fluid mechanics are very complex, so it has a lot of valves and actuators and a pretty complicated control system to make the machine operate very seamlessly and responsively.

Hydraulic Pumps Powering Excavators A Deep Dive into their Crucial Role

Hydraulic pumps are the role of the heart in an excavator hydraulic system. They turn the mechanical energy (normally from an engine) into dense, high-pressure hydraulic fluid. That high-pressure fluid is then fed throughout the machine to do work.

Various types of pumps, including gear pumps, piston pumps, and vane pumps, provide different characteristics in performance, resulting in differences in output power and efficiency. It all depends on the particular machine and how it will be operating.

Actuator Control and Precision

Hydraulic pumps deliver pressurized fluid to hydraulic cylinders and hydraulic motors – aka the actuators. The hydraulic energy is then converted into linear or rotary motion via the actuators that operate the excavator\\\'s arm, bucket and other implements.

Confidently controlled hydraulic flow adjusts the flow and speed of these motions allowing for both finesse such as fine digging and material manipulation to heavy lifting and demolition tasks.

System Reliability and Maintenance

Excavators: Regular hydraulic pump maintenance helps extend the life of the excavator and boost performance. Efficiency can be severely impacted by leaks, wear and contamination, resulting in catastrophic failures.

REPORT