-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Innovative PCB Designs For Enhanced Filter And Power Amplifier Performance In Wireless Systems

In the rapidly evolving landscape of wireless communication, from 5G networks to the Internet of Things (IoT), the demand for higher data rates, lower latency, and greater reliability is relentless. At the heart of every wireless transceiver lie two critical components: filters and power amplifiers (PAs). Filters ensure signal purity by isolating desired frequency bands and rejecting interference, while power amplifiers boost signal strength for transmission over long distances. However, their performance is intrinsically tied not just to their semiconductor design but to the printed circuit board (PCB) that hosts them. Traditional PCB layouts often introduce parasitic effects, signal loss, and thermal inefficiencies that bottleneck system performance. This article delves into the world of innovative PCB designs that are pushing the boundaries, enabling enhanced filter selectivity, efficiency, and power amplifier linearity and output power. By exploring advanced materials, novel structures, and integrated design philosophies, we uncover how next-generation PCBs are becoming active enablers of superior wireless system performance.

Advanced Substrate Materials and Laminates

The foundation of any high-performance PCB is its substrate material. For RF and microwave applications, standard FR-4 laminates often fall short due to their relatively high dielectric loss and inconsistent dielectric constant across frequencies. Innovative designs are increasingly adopting specialized materials like Rogers RO4000 series, PTFE-based substrates (e.g., Teflon), and ceramic-filled composites. These materials offer lower dissipation factors, which directly translate to reduced insertion loss for filters and higher efficiency for power amplifiers by minimizing energy wasted as heat within the board itself.

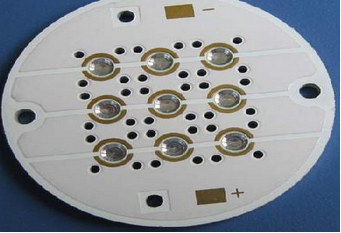

Furthermore, the thermal management properties of these advanced laminates are crucial. High-power amplifiers generate significant heat, which can degrade performance and reliability. Modern PCB designs incorporate substrates with high thermal conductivity, such as metal-core PCBs (e.g., aluminum or copper bases) or materials with engineered thermal vias. These features efficiently dissipate heat away from active PA components, maintaining optimal operating temperatures and ensuring stable, long-term performance. This material-level innovation is the first critical step in building a PCB that can support the rigorous demands of advanced wireless systems.

Embedded and 3D Passive Component Integration

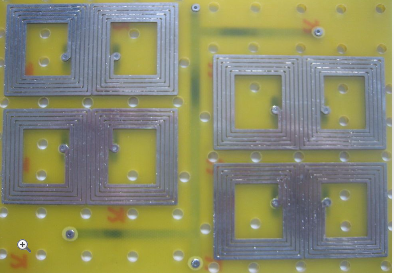

Moving beyond surface-mounted devices, a transformative approach involves embedding passive components—resistors, capacitors, and inductors—within the PCB layers themselves. For filters, this allows for the creation of highly precise and compact resonant structures, such as embedded planar filters, cavity resonators, or even substrate integrated waveguide (SIW) filters. By embedding these elements, designers achieve superior control over parasitic inductance and capacitance, leading to filters with sharper roll-off, better out-of-band rejection, and reduced board footprint.

For power amplifiers, embedding decoupling capacitors and impedance matching networks directly into the PCB substrate minimizes parasitic loop inductance. This is vital for maintaining stability at high frequencies and providing clean, instantaneous power to the PA die. The 3D integration of these passives also shortens interconnection paths, reducing loss and phase distortion. This holistic integration transforms the PCB from a mere carrier into a sophisticated, multi-functional platform that enhances the electrical performance of both filters and PAs by co-designing them with their supporting circuitry.

Precision Electromagnetic Modeling and Layout Techniques

The performance leap in modern PCBs is heavily reliant on sophisticated electromagnetic (EM) simulation tools. Before a single board is fabricated, designers use 3D full-wave simulators to model the entire layout, accounting for effects like cross-talk, ground plane discontinuities, and radiation losses. For filters, this enables the precise design of microstrip or stripline structures with controlled impedance and coupling coefficients, directly influencing bandwidth and selectivity. EM modeling allows for the optimization of filter geometries to achieve desired responses that are robust against manufacturing tolerances.

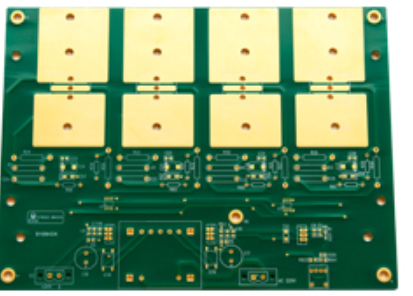

In power amplifier circuits, layout is paramount for efficiency and linearity. Innovative designs employ techniques like ground plane stitching, optimized via fields, and careful routing of RF traces to minimize ground bounce and provide a low-impedance return path. Thermal relief patterns are also simulated and optimized to manage heat distribution. The use of defected ground structures (DGS) or electromagnetic bandgap (EBG) layers within the PCB can suppress harmonic frequencies generated by the PA, improving spectral purity without adding bulky external filters. This simulation-driven, precision layout ensures that the theoretical performance of the components is fully realized in the physical implementation.

System-in-Package and Heterogeneous Integration

The ultimate frontier in innovative PCB design is its convergence with advanced packaging technologies. The System-in-Package (SiP) approach, where the filter, PA die, and other RF front-end components are integrated into a single package mounted on the PCB, drastically reduces interconnect lengths and parasitics. The PCB in this context may incorporate specialized build-up layers or fan-out wafer-level packaging (FOWLP) substrates that offer ultra-fine line spacing and multiple redistribution layers (RDLs).

This heterogeneous integration allows for the co-design of the filter and PA in an unprecedented way. For instance, a bandpass filter can be designed as part of the PA's output matching network, simultaneously performing impedance transformation and harmonic filtering. The PCB substrate acts as the interposer or package body, facilitating short, low-loss interconnects between the bare dies. This tight integration minimizes losses, improves power-added efficiency (PAE) of the amplifier, and enhances the overall system's noise figure and sensitivity, marking a significant step towards fully integrated and miniaturized wireless modules.

REPORT