-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

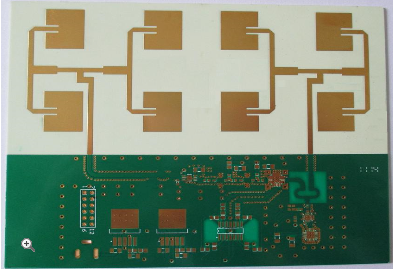

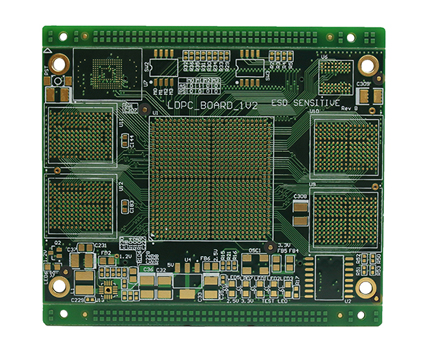

Practical Guidelines For Testing And Validating High Frequency PCBs To Meet Stringent Industry Standards And Ensure Long Term Reliability

In the rapidly evolving landscape of modern electronics, high-frequency printed circuit boards (PCBs) are the unsung heroes powering breakthroughs in telecommunications, aerospace, defense, and advanced computing. These intricate boards, operating at frequencies typically above 1 GHz, form the backbone of systems where signal integrity, minimal loss, and precise timing are non-negotiable. However, their sophisticated design and material requirements make them exceptionally vulnerable to a myriad of performance-degrading factors, from impedance mismatches and crosstalk to thermal management issues and manufacturing defects. As industry standards become increasingly stringent—driven by demands for 5G/6G connectivity, autonomous systems, and mission-critical applications—the traditional "build and hope" approach is a recipe for costly failures. This underscores the critical importance of a rigorous, methodical framework for testing and validation. This article delves into practical, actionable guidelines for ensuring that high-frequency PCBs not only meet the exacting benchmarks of today's standards like IPC, IEEE, and MIL-PRF-31032 but also demonstrate unwavering reliability throughout their operational lifespan, thereby safeguarding product integrity and brand reputation in competitive markets.

Comprehensive Pre-Manufacturing Design Validation and Simulation

The journey to a reliable high-frequency PCB begins long before the first layer is etched. Comprehensive design validation using advanced electromagnetic (EM) simulation tools is the first critical line of defense. Software suites like ANSYS HFSS, Cadence Sigrity, or Keysight ADS allow engineers to create a virtual prototype of the PCB. At this stage, it is imperative to perform detailed signal integrity (SI) and power integrity (PI) analyses. SI simulations model how high-speed signals propagate through traces, vias, and connectors, predicting potential issues such as reflection due to impedance discontinuities, attenuation from dielectric losses, and crosstalk from electromagnetic coupling between adjacent lines. Simultaneously, PI analysis ensures that the power delivery network (PDN) can provide stable, low-noise voltage to all components, as even minor fluctuations can cause timing jitter or false switching in sensitive RF circuits.

Furthermore, thermal simulations should be integrated into this phase. High-frequency components, such as power amplifiers, can generate significant heat. Using thermal modeling software, designers can identify potential hotspots and assess the effectiveness of the planned thermal management strategies, such as thermal vias, heatsinks, or substrate materials with high thermal conductivity. By identifying and rectifying these issues in the virtual domain, teams can avoid costly and time-consuming design spins later. This pre-manufacturing validation sets a solid foundation, ensuring the design is robust and optimized for performance before committing to physical production.

Material Selection and Characterization for Consistent Performance

The substrate material is the very foundation of a high-frequency PCB's performance. Unlike standard FR-4, high-frequency applications demand laminates with low and stable dielectric constant (Dk) and dissipation factor (Df) across the target frequency range and operating temperatures. Materials like Rogers RO4000 series, Taconic RF-35, or Isola's Astra MT77 are common choices. A key practical guideline is to not solely rely on datasheet values from manufacturers. In-house characterization of the laminate's Dk and Df at the relevant frequencies is crucial, as these properties can vary with frequency, temperature, and even humidity. This involves fabricating simple test coupons, such as microstrip or stripline resonators, and measuring them using a vector network analyzer (VNA) to extract the material's actual RF properties.

Equally important is the selection and specification of the copper foil. The surface roughness of the copper can significantly impact insertion loss at higher frequencies, as the signal tends to travel more on the conductor's surface due to the skin effect. Specifying low-profile or reverse-treated foils can minimize this roughness-induced loss. Consistency in material procurement must be enforced; any batch-to-batch variation in the laminate or copper can lead to unpredictable shifts in impedance and loss, jeopardizing yield and performance. Therefore, establishing a qualified materials list (QML) and conducting regular incoming inspections are vital steps in the validation workflow.

Impedance Control and Fabrication Process Monitoring

Maintaining consistent characteristic impedance (typically 50 or 75 ohms) across all critical traces is paramount for signal integrity. This requires precise control over trace width, thickness, and the dielectric height, which are all subject to manufacturing tolerances. Practical guidelines mandate close collaboration with the PCB fabricator. Providing them with detailed impedance control drawings that specify the target impedance, tolerance (often as tight as ±5%), and the stack-up is essential. It is advisable to include impedance test coupons on the fabrication panel—separate from the main board but made with the same process—to allow for non-destructive testing.

During fabrication, process control monitors (PCMs) should be used to track key parameters. These include copper plating thickness, dielectric layer thickness, and etch uniformity. Techniques like time-domain reflectometry (TDR) are then used to measure the impedance profile of the actual traces on the finished board or coupon. Any deviation outside the specified tolerance must be investigated and corrected. This level of process monitoring ensures that the as-built PCB matches the simulated design, preventing impedance mismatches that can cause signal reflections, degraded eye diagrams, and ultimately, system failure.

Rigorous Post-Manufacturing Electrical and Environmental Testing

Once the PCB is assembled with components, a battery of post-manufacturing tests must be conducted. The cornerstone of electrical testing is S-parameter measurement using a calibrated Vector Network Analyzer (VNA). S-parameters (Scattering parameters) like S11 (return loss) and S21 (insertion loss) quantitatively describe how the network behaves at high frequencies, revealing losses, resonances, and bandwidth limitations. These measurements should be compared directly against the simulation models to verify performance.

Beyond basic S-parameters, other critical tests include eye diagram analysis for high-speed digital signals to assess jitter and noise margins, and phase noise measurements for oscillators and clock circuits. Environmental stress testing is the other pillar of long-term reliability validation. This involves subjecting the assembled PCB to temperature cycling, thermal shock, humidity exposure, and vibration tests as per relevant industry standards (e.g., IPC-TM-650, MIL-STD-810). These tests accelerate aging and uncover latent defects such as delamination, solder joint fatigue, or changes in material properties that could lead to field failures. Only boards that pass both the electrical performance benchmarks and the environmental stress screens can be considered validated for long-term, reliable operation in their intended application.

Documentation, Traceability, and Continuous Improvement

The final, often overlooked, set of guidelines revolves around robust documentation and a culture of continuous improvement. Every step of the testing and validation process—from simulation reports and material certificates to impedance measurements and environmental test results—must be meticulously documented. This creates a complete audit trail, essential for compliance with industry standards and for troubleshooting any issues that arise in the field. Traceability of materials, fabrication lots, and assembly batches allows for targeted corrective actions if a failure trend is identified.

Furthermore, data from the validation process should feed directly back into the design and manufacturing cycles. Correlating test failures with specific design choices or process steps enables root cause analysis. This closed-loop feedback system is the engine of continuous improvement, allowing engineering teams to refine their models, tighten their specifications, and partner more effectively with fabricators. By institutionalizing these practices, organizations can systematically enhance the performance, yield, and reliability of their high-frequency PCB products, turning validation from a final gate into a powerful tool for innovation and quality assurance.

REPORT