-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Featured Blogs

The Artistry of Wigs: Exploring the Beauty, Versatility, and Cultural Significance of Wigs in Fashion and Everyday Life Across the Globe is a fascinating journey into the world of wigs, uncovering their transformative power and deep-rooted cultural meanings. From ancient civilizations to modern runways, wigs have played a pivotal role in self-expression, identity, and artistry. This exploration delves into how wigs transcend mere fashion accessories, becoming symbols of creativity, tradition, and societal norms.

The Historical Evolution of Wigs

Wigs have a rich history that dates back thousands of years. In ancient Egypt, wigs were worn by both men and women as symbols of status and protection from the sun. The elaborate designs often featured braids and beads, reflecting the artistry of the time.

During the 17th and 18th centuries in Europe, wigs became a staple of aristocratic fashion. Powdered wigs, or perukes, were synonymous with wealth and power, adorning the heads of kings and nobles. This era highlighted the wig's role as a marker of social hierarchy.

Wigs in Modern Fashion

Today, wigs are celebrated for their versatility in the fashion industry. Designers and stylists use wigs to create bold, avant-garde looks on runways, pushing the boundaries of creativity. From neon-colored wigs to realistic human hair pieces, the possibilities are endless.

Celebrities and influencers also embrace wigs as a tool for reinvention. Stars like Lady Gaga and Rihanna have popularized the use of wigs to experiment with different personas, proving that wigs are more than just accessories—they are extensions of identity.

Cultural Significance of Wigs

In many cultures, wigs hold profound symbolic meaning. In Japan, traditional wigs, or katsura, are used in theater performances like Kabuki to portray characters and emotions. These wigs are meticulously crafted to preserve cultural heritage.

In African communities, wigs and hairpieces are often tied to notions of beauty and pride. The vibrant styles and textures celebrate diversity and serve as a connection to ancestral traditions. Wigs here are not just fashion statements but also cultural affirmations.

Wigs in Everyday Life

Beyond fashion and culture, wigs play a practical role in everyday life. For individuals experiencing hair loss due to medical conditions, wigs offer a sense of normalcy and confidence. High-quality, natural-looking wigs can be life-changing.

Additionally, wigs provide a low-commitment way to experiment with different looks. Whether for a special occasion or a daily change, wigs allow people to express themselves without permanent alterations to their natural hair.

-

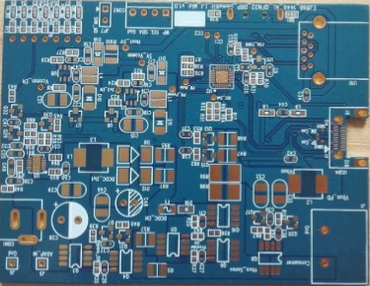

Advanced impedance control in multilayer printed circuit board (PCB) manufacturing represents a significant advancement in electronics manufacturing services (EMS). Traditional PCB fabrication often struggles to maintain consistent impedance across large, complex boards, especially in high-frequency applications. This inconsistency leads to signal integrity issues, reduced performance, and even system failure. Advanced impedance control techniques, however, mitigate these problems, enabling the creation of high-performance electronic devices. This process involves a meticulous approach to material selection, design, and manufacturing, which ultimately enhances the reliability and functionality of the final product.

Advanced impedance control in multilayer printed circuit board (PCB) manufacturing represents a significant advancement in electronics manufacturing services (EMS). Traditional PCB fabrication often struggles to maintain consistent impedance across large, complex boards, especially in high-frequency applications. This inconsistency leads to signal integrity issues, reduced performance, and even system failure. Advanced impedance control techniques, however, mitigate these problems, enabling the creation of high-performance electronic devices. This process involves a meticulous approach to material selection, design, and manufacturing, which ultimately enhances the reliability and functionality of the final product.Material Selection and Characterization

The foundation of advanced impedance control lies in careful material selection. Dielectric materials play a crucial role in determining the impedance of the PCB. Manufacturers must select materials with precise dielectric constants and low dissipation factors to maintain impedance consistency. This often involves rigorous testing and characterization of materials to ensure they meet the specified tolerances. Advanced techniques, such as time-domain reflectometry (TDR), are employed to measure the dielectric properties of the materials with high accuracy.

Furthermore, the metallization layers, typically copper, must possess consistent thickness and surface roughness. Variations in these parameters directly affect the characteristic impedance. Precise control over plating processes is crucial, often involving techniques like electroless plating and electroplating with stringent monitoring to ensure uniformity across the entire board.

Design for Impedance Control

Effective impedance control begins with the PCB design stage. Computer-aided design (CAD) software plays a pivotal role in simulating and predicting impedance characteristics. Engineers utilize specialized software packages to model the signal paths, considering the dielectric properties of the materials and the geometry of the traces. This allows for optimization of trace width, spacing, and layer stacking to achieve the desired impedance.

Controlled impedance design incorporates specific trace geometries and spacing to ensure consistent impedance across the entire signal path. This may involve using microstrip, stripline, or embedded coplanar waveguide structures, each with its own impedance characteristics. Careful consideration is given to the via placement and design to minimize impedance discontinuities. These design optimizations are critical for maintaining signal integrity in high-speed applications.

Manufacturing Processes and Quality Control

The manufacturing process itself is crucial for realizing the designed impedance. Precise control over the etching and drilling processes is essential to maintain the fidelity of the trace geometry. Advanced techniques, such as laser ablation, offer greater precision compared to traditional chemical etching. Real-time monitoring of the manufacturing process using automated optical inspection (AOI) and other quality control measures helps to identify and rectify any deviations from the design specifications.

After the manufacturing process, rigorous testing is performed to verify the achieved impedance. TDR is frequently employed to measure the impedance along critical signal paths. This provides feedback for process optimization and ensures the PCB meets the required specifications. This comprehensive testing and quality control measures ensure the final product meets the desired impedance characteristics and signal integrity requirements.

Advanced Monitoring and Feedback Systems

The most advanced EMS facilities employ sophisticated monitoring and feedback systems to ensure consistent impedance throughout the entire manufacturing process. These systems integrate data from various stages, such as material characterization, design simulation, and manufacturing processes, to provide real-time feedback and adaptive control. This allows for quick identification and correction of any deviations, improving yield and reducing waste.

Ultimately, the implementation of advanced impedance control techniques in multilayer PCB EMS manufacturing results in higher performance, reliability, and reduced time-to-market for a wide range of electronic products. The investment in sophisticated equipment, materials, and expertise is justified by the significant improvements in product quality and reduced development costs associated with troubleshooting signal integrity issues.

2025-05-24szshuoqiang -

Superior Flat Flexible Cables for High End Avionics PCBs

In the rapidly evolving world of avionics, the demand for high-performance, reliable, and lightweight components has never been greater. Among these critical components, Superior Flat Flexible Cables (FFCs) have emerged as a game-changer for High-End Avionics Printed Circuit Boards (PCBs). These cables are designed to meet the stringent requirements of modern aerospace systems, offering unparalleled flexibility, durability, and signal integrity. Whether it's for commercial aircraft, military jets, or space exploration vehicles, Superior FFCs are becoming the go-to solution for engineers looking to optimize performance while reducing weight and space.

The aerospace industry is known for its extreme operating conditions, including high vibrations, temperature fluctuations, and electromagnetic interference. Traditional wiring solutions often fall short in such environments, leading to increased maintenance costs and potential system failures. Superior FFCs, however, are engineered to withstand these challenges, making them an ideal choice for high-end avionics. This article delves into the unique features and benefits of these cables, exploring why they are revolutionizing the avionics industry.

Unmatched Flexibility and Space Efficiency

One of the most significant advantages of Superior Flat Flexible Cables is their unmatched flexibility. Unlike traditional round cables, FFCs can bend and twist without compromising their performance. This flexibility is crucial in avionics, where space is at a premium, and every millimeter counts. Engineers can route these cables through tight spaces and around obstacles, ensuring optimal use of available real estate within the aircraft's electronic systems.

Moreover, the flat design of these cables allows for a higher density of conductors in a thinner profile. This means that more signals can be transmitted through a smaller space, reducing the overall weight of the wiring harness. In aerospace applications, weight reduction is a critical factor, as it directly impacts fuel efficiency and operational costs. By replacing bulky round cables with sleek FFCs, manufacturers can achieve significant weight savings without sacrificing performance.

Superior Signal Integrity and EMI Shielding

High-end avionics systems rely on the precise transmission of signals to ensure safe and efficient operation. Superior FFCs are designed to maintain excellent signal integrity, even in the presence of electromagnetic interference (EMI). This is achieved through advanced shielding techniques that protect the cables from external noise and crosstalk. The result is a reliable and noise-free signal transmission, which is essential for critical avionics functions such as navigation, communication, and flight control.

Additionally, the materials used in Superior FFCs are carefully selected to minimize signal loss and distortion. High-quality dielectrics and conductive materials ensure that the cables can handle high-frequency signals with minimal attenuation. This makes them ideal for modern avionics systems, which increasingly rely on high-speed data transmission for real-time monitoring and control.

Durability and Reliability in Harsh Environments

Avionics systems operate in some of the harshest environments imaginable, from the extreme cold of high altitudes to the intense heat of engine compartments. Superior FFCs are built to withstand these conditions, thanks to their robust construction and high-quality materials. The cables are resistant to temperature extremes, moisture, chemicals, and UV radiation, ensuring long-term reliability even in the most demanding applications.

Furthermore, the flat flexible design of these cables reduces the risk of mechanical failure due to vibrations and shocks. Traditional cables with multiple strands are more prone to breakage under constant movement, but FFCs distribute stress more evenly, enhancing their durability. This makes them an excellent choice for avionics systems that are subject to high levels of vibration, such as those in aircraft engines and landing gear.

Ease of Installation and Maintenance

Another key benefit of Superior FFCs is their ease of installation and maintenance. The flat and flexible nature of these cables allows for quick and straightforward routing, reducing the time and labor required for assembly. This is particularly advantageous in the aerospace industry, where downtime can be incredibly costly. Engineers can easily connect and disconnect FFCs, simplifying both initial installation and future maintenance.

Additionally, the modular design of these cables enables easy replacement of individual components without the need to rewire entire systems. This not only reduces maintenance costs but also minimizes the risk of errors during repairs. With Superior FFCs, avionics systems can be kept in optimal condition with minimal effort, ensuring uninterrupted operation and enhanced safety.

Future-Proofing Avionics Systems

As avionics technology continues to advance, the need for future-proof solutions becomes increasingly important. Superior FFCs are designed with scalability in mind, allowing for easy upgrades and modifications. Their high-density conductor arrangement and compatibility with high-speed data transmission make them well-suited for next-generation avionics systems, including those incorporating artificial intelligence and advanced sensor networks.

By adopting Superior FFCs, manufacturers can ensure that their avionics systems remain at the cutting edge of technology. These cables provide the flexibility, performance, and reliability needed to meet the evolving demands of the aerospace industry, making them an indispensable component for high-end avionics PCBs.

2025-08-09szshuoqiang -

LED Lighting Solutions For Modern Homes And Offices Bright Efficient And Eco Friendly

In an era where sustainability meets innovation, LED lighting has revolutionized how we illuminate modern homes and offices. These solutions are not just about brightness; they represent a shift towards energy efficiency and environmental responsibility, making them a top choice for contemporary spaces seeking both style and substance.

Energy Efficiency and Cost Savings

LED lights consume significantly less electricity compared to traditional incandescent or fluorescent bulbs, leading to substantial reductions in energy bills. For instance, they use up to 80% less power while delivering the same level of illumination, which translates to long-term savings for households and businesses alike.

Moreover, their lower energy consumption reduces the strain on power grids, contributing to broader energy conservation efforts. This makes LEDs an economically smart and sustainable investment for any modern setting.

Environmental Benefits

LED lighting is eco-friendly due to its minimal environmental impact. These lights contain no toxic materials like mercury, which is often found in fluorescent bulbs, and they are fully recyclable, reducing landfill waste.

Additionally, their long lifespan means fewer replacements, which cuts down on manufacturing and disposal-related pollution. By choosing LEDs, users actively support a greener planet through reduced carbon footprints and resource conservation.

Brightness and Versatility

LEDs offer superior brightness with options for various color temperatures, from warm whites for cozy homes to cool whites for focused office environments. This adaptability allows for customized lighting that enhances mood and productivity in different spaces.

They also come in diverse designs, including dimmable and smart-enabled variants, integrating seamlessly with modern home automation systems for convenience and efficiency.

2025-09-15tuiguang2 -

Imagine you\'re rushing to catch a flight or heading out for a weekend getaway. Amidst the excitement, there\'s often that moment of frustration when you\'re digging through a cluttered suitcase or oversized tote, searching for your favorite lipstick or a crucial skincare item. This common travel dilemma is precisely why the right accessory can transform your journey. Enter the stylish and compact mini makeup bag—a modern solution designed to keep your beauty essentials organized, accessible, and protected, no matter where your adventures take you. In today\'s fast-paced world, where efficiency meets elegance, this little bag isn\'t just an add-on; it\'s a game-changer for anyone who values both practicality and style. Whether you\'re a frequent flyer, a busy professional, or simply someone who loves to stay prepared, this travel essential promises to simplify your routine, allowing you to focus on the experiences ahead. Let\'s explore how this clever design elevates everyday travel, blending form and function to become an indispensable companion for beauty enthusiasts everywhere.

Unmatched Organization and Efficiency

One of the standout features of this mini makeup bag is its ability to bring order to chaos. With dedicated compartments and smart pockets, it ensures that every item has its place, from brushes and palettes to serums and lip glosses. No more jumbled messes or spilled products—everything stays neatly arranged, saving you precious time during your travels. This level of organization is especially valuable in tight spaces, like airplane bathrooms or hotel rooms, where quick access can make all the difference.

Moreover, the bag\'s thoughtful layout encourages a minimalist approach. By limiting space, it prompts you to prioritize only your must-have beauty products, reducing unnecessary clutter in your luggage. This not only lightens your load but also promotes a more mindful packing habit. Over time, users find that this efficiency translates into smoother, stress-free trips, allowing them to maintain their beauty routines without compromise.

Compact and Lightweight Design

Despite its small size, this makeup bag is engineered to maximize storage without adding bulk. Crafted from durable yet lightweight materials, it slips easily into carry-ons, backpacks, or even large purses, making it the perfect companion for any type of travel. Its compact nature doesn\'t sacrifice capacity; instead, it utilizes clever folding or expandable features to accommodate more than you\'d expect. This balance of portability and functionality is key for modern travelers who seek to pack smart.

Additionally, the bag\'s slim profile ensures it won\'t take up valuable space in your luggage. Whether you\'re hopping between cities or embarking on a long-haul flight, its lightweight construction means you can bring your entire beauty arsenal without feeling weighed down. This design philosophy reflects a growing trend toward sustainable travel, where every item must earn its place by offering versatility and ease.

Stylish Aesthetics and Durability

Beyond practicality, this mini makeup bag is a fashion statement in its own right. Available in a range of chic colors, patterns, and textures, it complements your personal style while serving a functional purpose. From sleek minimalist designs to bold, vibrant prints, there\'s an option to suit every taste. This aesthetic appeal makes it more than just a storage solution—it\'s an accessory you\'ll be proud to display, whether on a vanity or during transit.

Durability is another critical aspect. Made from high-quality materials like water-resistant nylon or vegan leather, the bag is built to withstand the rigors of travel. Reinforced zippers, sturdy stitching, and easy-to-clean surfaces ensure it remains in pristine condition, trip after trip. This longevity not only offers great value but also aligns with eco-conscious choices, as a well-made product reduces the need for frequent replacements.

Versatility for Various Lifestyles

While designed with travel in mind, this makeup bag\'s utility extends far beyond vacations. It\'s equally suited for daily use, such as carrying essentials to the gym, office, or social events. Its adaptable nature means it can store anything from makeup and skincare to tech accessories, medications, or small toiletries, making it a versatile tool for organization in all aspects of life. This multifunctionality is a testament to its thoughtful design, catering to diverse needs without compromising on style.

For those with active lifestyles, the bag\'s compact size and secure closures prevent spills and damage, even during movement. Students, professionals, and parents alike can appreciate how it streamlines their daily routines, proving that great design is about enhancing everyday experiences. By bridging the gap between travel and daily use, it becomes a reliable staple in your collection, ready for any scenario.

Effortless On-the-Go Experience

Ultimately, the true value of this mini makeup bag lies in the seamless experience it provides. Its user-friendly features, such as easy-open zippers, transparent pockets, or hanging hooks, are designed with real-world convenience in mind. These small details add up to create a hassle-free routine, whether you\'re touching up makeup in a crowded airport or refreshing your skincare after a long day of exploration. This focus on effortless usability is what sets it apart as a travel essential.

By integrating this bag into your travel kit, you\'re not just organizing products—you\'re investing in peace of mind. It empowers you to stay prepared and polished, no matter where life takes you. As travel continues to evolve, tools like this highlight the importance of blending innovation with simplicity, proving that the best essentials are those that make our journeys smoother and more enjoyable.

2025-12-12dgdiwoli

Latest Blogs

Aluminum Frame Luggage with Modern Design for Wholesale and Custom OEM/ODM Orders

Aluminum frame luggage is a premium travel solution defined by its robust aluminum skeleton, offering superior structural integrity and a modern aesthetic. For B2B buyers, its core value lies in securing a reliable, high-margin product line through factory-direct OEM/ODM services, including custom logo and packaging, which streamline the supply chain.

Technical Specifications of Modern Suitcase Design

The modern design of aluminum luggage directly addresses key B2B pain points. Its durability ensures a premium product that withstands the rigors of travel, protecting your brand reputation. The availability of OEM/ODM services and factory-direct wholesale models provides a competitive price point and complete customization control, from logo application to bespoke packaging, ensuring consistent quality for private label or corporate gifting programs.

| Specification | Details |

|---|---|

| Material (Frame) | Aluminum |

| Style | Modern, Luxury |

| Business Model | OEM/ODM, Wholesale |

| Customization | Logo, Packaging |

How Durable is Aluminum Frame Luggage?

Aluminum frame luggage is exceptionally durable, offering superior resistance to impact and crushing compared to many soft-side or inferior frame materials. The aluminum skeleton provides a rigid structure that protects contents and maintains the suitcase's shape under stress. This makes it an ideal choice for wholesale buyers seeking products that reduce returns and enhance customer satisfaction through long-term reliability.

Aluminum vs Polycarbonate Luggage for Wholesale

For wholesale, aluminum luggage typically offers a more premium, luxury perception and structural rigidity, while polycarbonate is known for flexibility and lighter weight. The choice depends on your target market: aluminum suits brands focusing on high-end travel, corporate gifting, and professional image. It provides a distinct aesthetic advantage that can command higher retail prices and strengthen brand positioning in competitive markets.

Are OEM Luggage Cases Certified for Travel?

Reputable OEM partners ensure luggage meets international travel standards, though specific certifications should always be verified directly with the manufacturer. While general certifications are crucial for safety and airline compliance, B2B buyers must discuss testing protocols and compliance documentation with their OEM provider. A reliable factory will transparently share its quality control processes and adherence to relevant material and construction standards.

Ideal Applications and Target Audience

This product is engineered for specific commercial segments. Luggage Wholesalers and Distributors benefit from a durable, high-demand product with strong margins. Travel Gear Retail Brands (Private Label) leverage the full OEM/ODM capabilities to build a unique, branded collection with modern aesthetics. Corporate Gift and Promotional Product Buyers utilize the sturdy, professional appearance of aluminum luggage to reflect and elevate their company's brand value in bulk gifting programs.

- Superior durability from a robust aluminum frame structure.

- Complete customization through OEM/ODM services for logos and packaging.

- Competitive factory-direct wholesale pricing for improved ROI.

- Modern luxury design that appeals to high-end markets and corporate clients.

- A reliable supply chain partner for consistent quality in bulk orders.

Trusted by businesses for its factory-backed capabilities in custom manufacturing and direct wholesale, aluminum frame luggage remains a cornerstone for building a credible and profitable travel gear portfolio.

Superlight Unbreakable PP Luggage Set with 4-Piece Trendy Design for Effortless and Durable Travel

Lightweight luggage is designed to minimize weight without sacrificing durability, directly addressing the common traveler's pain point of excessive airline baggage fees. The Superlight Unbreakable PP Luggage Set exemplifies this by using advanced polypropylene to offer a robust yet remarkably light travel solution.

Unbreakable PP Luggage: Built for Durability and Style

This luggage set tackles the frustration of cracked or broken suitcases during rough airport handling. The unbreakable PP (Polypropylene) material provides superior impact resistance compared to standard hard shells, while the trendy design ensures your travel gear looks coordinated. The 4-piece set offers versatile sizing for different trip lengths, solving the need for sufficient luggage for family vacations without a high cost.

| Specification | Details |

|---|---|

| Material | Unbreakable PP (Polypropylene) |

| Set Pieces | 4 (e.g., likely includes various suitcase sizes) |

| Weight Class | Superlight |

| Design Style | Trendy |

How does superlight luggage save on airline fees?

Superlight luggage saves money by keeping your suitcase weight well below airline limits, preventing costly overweight charges. Airlines often charge significant fees for bags exceeding 50 pounds. By starting with a lighter suitcase frame, you have more weight allowance for your belongings. This set's superlight construction maximizes your packing capacity without the risk of extra fees.

Why choose unbreakable PP over standard hard shell luggage?

Unbreakable PP luggage offers greater flexibility and crack resistance than rigid hard shell materials like polycarbonate. While polycarbonate can shatter on severe impact, polypropylene is designed to absorb shocks and return to its original shape. This makes it a more durable choice for frequent travel and rough baggage handling, ensuring your luggage lasts for many journeys.

Is superlight luggage durable for frequent travel?

Yes, when constructed with materials like unbreakable PP, superlight luggage is highly durable for frequent use. The key is the engineering of the material to be both light and tough. This luggage set is built to withstand the repeated stresses of check-in, conveyor belts, and stacking, making it a reliable long-term investment for regular travelers.

Who is this luggage set for?

This set is ideal for specific traveler profiles. Frequent leisure travelers will appreciate the durability and weight savings on every trip. Budget-conscious vacationers benefit directly from avoiding overweight baggage fees. Finally, families needing multiple luggage pieces find value in a coordinated, cost-effective set that meets the needs of different family members for various trip types.

- Maximizes packing weight allowance to avoid airline overweight fees.

- Constructed from crack-resistant polypropylene for long-lasting durability.

- Includes four coordinated pieces for versatile travel needs.

- Features a modern, trendy design for stylish travel.

- Solves the need for reliable, multi-piece luggage at a family-friendly value.

Choosing travel gear from reputable manufacturers ensures you get the promised blend of superlight construction and unbreakable performance for a smoother journey.

Customized Fashionable Luggage with 20-24-28 Inch Sizes for OEM/ODM Wholesale and Branding Solutions

Custom luggage refers to suitcases and travel bags manufactured to a brand's exact specifications, offering a critical advantage for businesses seeking to differentiate themselves in the competitive travel market. This process leverages specialized OEM/ODM manufacturing capabilities to transform unique designs into durable, market-ready products.

Technical Specifications for OEM Luggage Manufacturing

For luggage brand startups and fashion retailers, the ability to translate a vision into a tangible product is paramount. Our customizable manufacturing process directly addresses the pain point of lacking in-house production capability, ensuring that every detail—from material selection to hardware finishes—aligns with your brand identity and quality standards for bulk orders.

| Specification | Details |

|---|---|

| Product Type | Luggage / Suitcase |

| Available Sizes | 20 Inch, 24 Inch, 28 Inch |

| Key Feature | Customizable / Fashionable Design |

| Business Model | OEM/ODM, Wholesale |

How to customize luggage for my brand?

The customization process begins with a detailed consultation to define your design, materials, and branding requirements before moving into prototyping. This collaborative phase ensures your logo placement, color schemes, and functional features are perfectly integrated. The factory's capabilities then translate these specs into a production sample for final approval, streamlining the path from concept to finished inventory.

Why choose OEM for fashion luggage manufacturing?

OEM manufacturing provides access to specialized expertise, advanced production technology, and economies of scale that are otherwise inaccessible to most brands. This partnership allows you to offer trendy, fashionable luggage without the capital expenditure of building a factory. It shifts your focus to design, marketing, and sales while relying on a proven supply chain for consistent quality and timely delivery.

Are customized luggage products safe and durable?

Yes, professionally manufactured custom luggage from a capable OEM partner is engineered to meet rigorous safety and durability standards. The construction utilizes reinforced frames, quality zippers, and impact-resistant materials specified during the design phase. While specific certifications are brand-dependent, a reputable manufacturer will adhere to international norms for product safety and luggage testing protocols.

Ideal Applications and Target Audience

This OEM solution is engineered for specific business models. Luggage Brand Startups can launch a full product line without upfront factory investment. Fashion Retailers Expanding into Travel can leverage their design ethos to create cohesive, branded travel collections. Corporate Gift Suppliers require reliable, customizable bulk products for high-value promotions, where branded luggage serves as a premium, functional item for clients or employees.

- Full design control over materials, colors, and hardware for complete brand alignment.

- Scalable production across three standard sizes (20", 24", 28") to meet wholesale and bulk order demands.

- OEM/ODM partnership model that handles complex manufacturing, letting you focus on brand growth.

- A direct solution for businesses lacking in-house production capability but needing unique, branded inventory.

- Access to manufacturing expertise that ensures the final product is both fashionable and functionally durable for travel.

Businesses trust this model for its streamlined supply chain integration and commitment to turning branded concepts into commercial realities.

Aluminum Trolley Luggage with 360° Spinner Wheels for Wholesale and Custom OEM Orders

Aluminum trolley luggage is a premium category of travel cases defined by a sturdy aluminum frame, offering superior durability and a professional aesthetic for frequent travelers and business use. For wholesalers and brands, sourcing directly from a factory with OEM/ODM and custom logo capabilities ensures competitive pricing, consistent quality, and complete branding control.

Technical Specifications for Wholesale Custom OEM Luggage

For B2B buyers, the technical construction directly addresses core pain points: the aluminum frame provides exceptional impact resistance for long-term durability in bulk logistics, while the 360° spinner wheels ensure smooth maneuverability, a key feature for end-user satisfaction. The integrated OEM/ODM service model allows partners to bypass intermediaries, achieving better margins and tailored product development from design to delivery.

| Specification | Details |

|---|---|

| Material | Aluminum frame |

| Wheel Type | 360° spinner wheels |

| Handle | Telescopic handle |

| Service Type | OEM/ODM, Custom Logo |

How does the aluminum frame improve luggage durability?

An aluminum frame significantly improves luggage durability by providing a rigid, impact-resistant skeleton that protects the contents and maintains the case's structural integrity under stress. Unlike soft-shell designs or plastic frames, aluminum offers superior resistance to crushing, bending, and impact damage commonly encountered during air travel and handling. This translates to a longer product lifecycle, fewer returns for wholesalers, and higher perceived value for the end customer.

Why choose this factory for custom travel trolley manufacturing?

Choosing a factory with direct manufacturing and dedicated OEM/ODM services is crucial for ensuring product quality, design flexibility, and supply chain efficiency for custom travel trolleys. Such factories control the entire production process, from material sourcing to final assembly, which minimizes defects and ensures consistency across large bulk orders. Their expertise in custom logos and designs allows brands to create unique products without compromising on the core construction quality.

What quality control standards are used for OEM luggage production?

Reputable OEM luggage factories implement rigorous in-house quality control protocols at every stage of production, from raw material inspection to final pre-shipment checks. While specific international certifications (like ISO) are a strong trust signal, the absence of stated certifications does not preclude stringent quality management. A competent factory will have standardized procedures for testing wheel rotation, handle mechanism strength, zipper durability, and overall finish to meet the specifications agreed upon with the client.

Ideal Applications and Target Audience

This product and manufacturing model is specifically designed for commercial and partnership applications. Luggage wholesalers and distributors benefit from the durable, high-quality product at factory-direct prices for profitable resale. Travel accessory brands seeking OEM partners can leverage the custom design capabilities to build their private label line without capital investment in production facilities. Furthermore, corporate gift and promotional product suppliers can procure sturdy, professional-looking luggage in bulk, customized with company logos, for high-impact corporate clients or events.

- Superior durability from a lightweight yet rigid aluminum frame structure.

- Enhanced user experience with smooth-rolling 360° spinner wheels.

- Complete branding control through custom OEM/ODM and logo services.

- Supply chain efficiency and cost advantages via direct factory sourcing.

- Scalable production for reliable fulfillment of large bulk orders.

Partnering with a specialized manufacturer that controls its production line is a strategic decision for businesses prioritizing quality, customization, and supply chain reliability in the travel goods sector.

Stainless steel sanitary ware refers to bathroom fixtures and accessories crafted from high-grade stainless steel, offering exceptional durability, hygiene, and a modern aesthetic ideal for both commercial and residential applications. For procurement managers and contractors, sourcing from suppliers with robust OEM/ODM services and custom design capabilities is critical for project-specific requirements.

Technical Specifications of Modern Bathroom Accessories

Modern stainless steel sanitary ware directly addresses key industry challenges. Its non-porous, high-polished surface resists corrosion, bacterial growth, and water spots, solving maintenance and hygiene issues in high-traffic areas. The inherent strength of stainless steel ensures longevity, reducing total cost of ownership by minimizing replacements. For architects and designers, the availability of custom OEM/ODM services allows for seamless integration of fixtures into unique project designs, ensuring aesthetic consistency and meeting precise specifications.

| Specification | Details |

|---|---|

| Material | Stainless Steel |

| Surface Finish | High Polished / Mirror |

| Design Style | Modern |

| Application | Bathroom, Washroom, Hotel, Residential |

| Customization | OEM/ODM, Size, Design |

What is the best material for durable bathroom fixtures?

For maximum durability and hygiene in demanding environments, 304 or 316 grade stainless steel is the superior material for bathroom fixtures. It outperforms materials like plastic, coated metals, or even ceramic in impact resistance and longevity. Unlike chrome-plated brass, stainless steel is solid throughout, so scratches do not expose a different substrate, maintaining its appearance and corrosion resistance over decades of use.

Stainless steel vs ceramic sanitary ware for hotels

Stainless steel sanitary ware is generally more practical for hotel applications than ceramic due to its superior durability and lower maintenance. Ceramic is prone to chipping and cracking from impact, a common occurrence in busy hotel settings. Stainless steel is highly resistant to such damage. Furthermore, its non-porous surface is easier to sanitize completely, supporting higher hygiene standards for guest safety.

Are stainless steel bathroom accessories easy to clean and maintain?

Yes, stainless steel bathroom accessories are exceptionally easy to clean and maintain, especially with a high-polished finish. Routine cleaning requires only a soft cloth, warm water, and mild detergent to remove water spots and soap residue. The material does not harbor bacteria or mold, and its resistance to most chemicals means it won't degrade from common cleaning agents, ensuring a consistently pristine appearance with minimal effort.

Ideal Applications and Target Audience

This product category is engineered for professionals who prioritize performance, aesthetics, and project reliability. Hotel and Resort Procurement Managers benefit from the reduced lifecycle costs and enhanced guest experience. Commercial Building Contractors and Architects value the structural integrity, customization options, and compliance with commercial building codes. Bathroom Renovation and Interior Design Firms leverage the modern design and finish consistency to create upscale, cohesive bathroom environments for their clients.

- Superior durability and corrosion resistance for long-term use in high-traffic areas.

- Enhanced hygiene with a non-porous, easy-to-clean surface that inhibits bacterial growth.

- Modern, high-polished aesthetic that complements contemporary architectural designs.

- Flexible OEM/ODM and customization support for bespoke project requirements.

- Reduced total cost of ownership through minimal maintenance and replacement needs.

For projects requiring reliable, custom-engineered bathroom solutions, partnering with a manufacturer offering comprehensive OEM/ODM services and an extensive product range is a strategic decision for quality and consistency.

Custom Men's Running Tights with Compression for Enhanced Performance and Muscle Support

Technical Features of Compression Gym Leggings

| Specification | Details |

|---|---|

| Product Type | Men's Running Tights / Gym Leggings |

| Style | Slim-fit, Compression, Baselayer |

| Primary Use Cases | Running, Gym, Basketball, Training |

| Key Feature | Customizable (Implied by title) |

How do compression tights improve athletic performance?

What are the benefits of custom men's running tights vs regular shorts?

Are these slim-fit gym leggings safe for sensitive skin?

Who Are Custom Running Tights For?

- Targeted compression for enhanced muscle support and reduced fatigue.

- Slim-fit, moisture-wicking design for maximum comfort and freedom of movement.

- Durable construction ideal for running, gym workouts, and basketball.

- Customizable options to achieve a perfect, performance-optimized fit.

Popular Blogs

-

Cabinet Connector Hardware And Cabinet Fasteners

Cabinet connector hardware and cabinet fasteners play a pivotal role in the world of cabinetry, ensuring that furniture is not only functional but also visually appealing. This specialized hardware helps in the assembly and longevity of cabinets, making it essential for homeowners, builders, and designers alike. With a variety of options available in the market, understanding these components is crucial for anyone looking to create durable and attractive cabinetry. This article explores the different types of cabinet connector hardware and fasteners, their importance, and how they contribute to successful cabinetry construction.

Understanding Cabinet Connector Hardware

Cabinet connector hardware refers to a range of components specifically designed to join sections of cabinetry together. These fittings are engineered to provide strong joints, which are vital for maintaining the structure's integrity over time. Common types of cabinet connectors include dowels, biscuits, cam locks, and metal brackets. Each of these options has its unique applications and advantages, making them suitable for different cabinetry needs.

Dowels are cylindrical rods that fit into pre-drilled holes of adjoining pieces, ensuring precise alignment and robust support. Biscuit joints utilize oval-shaped pieces of wood, known as biscuits, that fit into slots cut into the materials, providing strength and stability. Cam locks, often featured in ready-to-assemble furniture, allow for quick and secure joining with the help of a simple turn of a knob. Lastly, metal brackets are typically used for reinforcing corners and joints, adding an extra layer of support where it is needed most.

The Significance of Cabinet Fasteners

Cabinet fasteners are crucial for the assembly process as they provide the necessary means to hold cabinet components together. They come in various forms, including screws, nails, and specialized fasteners like pocket hole screws and Euro screws. Each type of fastener has its specific role, and choosing the right one can significantly impact the overall strength and durability of the cabinetry.

Screws are the most commonly used fasteners in cabinetry, renowned for their holding power. They are available in multiple designs, such as wood screws and machine screws, each catering to different materials and assembly methods. Nails, while less robust than screws, can be used in specific applications where speed is essential, such as when using pre-fabricated parts. Pocket hole screws allow for concealed joining, making them ideal for creating furniture with clean lines, while Euro screws typically facilitate drawer assembly and cabinet hinging by providing sturdy and discreet mounting points.

Materials and Their Impact

The materials used in cabinet connector hardware and fasteners also play a crucial role in their effectiveness. Common materials include steel, brass, and plastic, each offering distinctive benefits. Steel fasteners are durable and resistant to bending, making them suitable for heavier applications, while brass connectors offer a more aesthetic finish, particularly in exposed areas. On the other hand, plastic fasteners can provide lightweight options for temporary or low-stress applications.

Moreover, the finish of the materials can influence their performance. For example, coated or galvanized steel can resist rust and corrosion, which is vital in kitchen or bathroom environments where moisture is present. With advancements in technology, manufacturers also offer specialized coatings that enhance the appearance while maintaining strength, allowing for seamless integration into various design themes.

Installation Techniques and Considerations

Proper installation techniques significantly affect the overall performance of cabinet connectors and fasteners. When setting up cabinetry, it is essential to follow the manufacturer's instructions meticulously, as improper installation can lead to structural issues over time. For instance, ensuring that screws are not over-tightened can prevent wood from splitting, while allowing the predefined dowel holes to line up correctly is crucial for achieving a tight joint.

Moreover, alignment is key when assembling cabinets. Utilizing tools like clamps can help in maintaining the correct positioning during installation, ensuring that the cabinet frame remains square and stable. Additionally, pre-drilling holes for screws can mitigate the risk of damaging the wood, especially in hardwood materials. Understanding these installation techniques empowers builders and DIY enthusiasts to achieve better results in their cabinetry projects.

Choosing the Right Components for Your Project

When embarking on a cabinetry project, selecting the appropriate cabinet connector hardware and fasteners is vital for achieving both functionality and aesthetics. Assessing the specific needs of your project, including the type of materials you'll be working with, the level of stress the joint will endure, and the desired finish, will help inform your choices. Consulting with hardware experts or manufacturers can also provide valuable insights into the best products for your particular application.

In conclusion, cabinet connector hardware and fasteners are essential components that contribute significantly to the durability and functionality of cabinetry. By understanding the various types of connectors and fasteners available, as well as the importance of material and installation techniques, individuals can ensure that their cabinetry projects are both attractive and enduring. The right choices can transform ordinary furniture into beautiful and resilient installations, enhancing the overall value and appeal of any space.

gztoplink2025-01-24 -

The Artistry of Wigs: Exploring the Beauty, Versatility, and Cultural Significance of Wigs in Fashion and Everyday Life Across the Globe is a fascinating journey into the world of wigs, uncovering their transformative power and deep-rooted cultural meanings. From ancient civilizations to modern runways, wigs have played a pivotal role in self-expression, identity, and artistry. This exploration delves into how wigs transcend mere fashion accessories, becoming symbols of creativity, tradition, and societal norms.

The Historical Evolution of Wigs

Wigs have a rich history that dates back thousands of years. In ancient Egypt, wigs were worn by both men and women as symbols of status and protection from the sun. The elaborate designs often featured braids and beads, reflecting the artistry of the time.

During the 17th and 18th centuries in Europe, wigs became a staple of aristocratic fashion. Powdered wigs, or perukes, were synonymous with wealth and power, adorning the heads of kings and nobles. This era highlighted the wig's role as a marker of social hierarchy.

Wigs in Modern Fashion

Today, wigs are celebrated for their versatility in the fashion industry. Designers and stylists use wigs to create bold, avant-garde looks on runways, pushing the boundaries of creativity. From neon-colored wigs to realistic human hair pieces, the possibilities are endless.

Celebrities and influencers also embrace wigs as a tool for reinvention. Stars like Lady Gaga and Rihanna have popularized the use of wigs to experiment with different personas, proving that wigs are more than just accessories—they are extensions of identity.

Cultural Significance of Wigs

In many cultures, wigs hold profound symbolic meaning. In Japan, traditional wigs, or katsura, are used in theater performances like Kabuki to portray characters and emotions. These wigs are meticulously crafted to preserve cultural heritage.

In African communities, wigs and hairpieces are often tied to notions of beauty and pride. The vibrant styles and textures celebrate diversity and serve as a connection to ancestral traditions. Wigs here are not just fashion statements but also cultural affirmations.

Wigs in Everyday Life

Beyond fashion and culture, wigs play a practical role in everyday life. For individuals experiencing hair loss due to medical conditions, wigs offer a sense of normalcy and confidence. High-quality, natural-looking wigs can be life-changing.

Additionally, wigs provide a low-commitment way to experiment with different looks. Whether for a special occasion or a daily change, wigs allow people to express themselves without permanent alterations to their natural hair.

topmi052025-03-26 -

Superior Mixing Technology for Enhanced Production Output

In today's competitive manufacturing landscape, optimizing production output is paramount. Achieving this often hinges on seemingly minor details, one of the most crucial being the efficiency of mixing processes. Superior mixing technology is no longer a luxury but a necessity for businesses seeking to enhance production rates, improve product quality, and reduce operational costs. This technology encompasses a range of advancements that significantly impact various industries, from pharmaceuticals and food processing to chemicals and cosmetics.Improved Mixing Efficiency and Uniformity

Traditional mixing methods often suffer from inconsistencies, leading to variations in product quality and potentially wasted materials. Superior mixing technologies, such as high-shear mixers and specialized impeller designs, address this directly. These systems create more powerful and consistent mixing actions, ensuring a uniform distribution of ingredients throughout the entire batch. This uniformity translates to improved product consistency and reduces the need for rework or rejection of substandard products.

Furthermore, advanced process control systems integrated with these mixers allow for precise monitoring and adjustment of mixing parameters such as speed, time, and temperature. This level of control ensures optimal mixing efficiency and reproducibility, minimizing variations between batches and enhancing overall product quality.

Reduced Mixing Time and Increased Throughput

Faster mixing translates directly into increased production output. Superior mixing technologies, through their improved designs and more powerful capabilities, significantly reduce the overall mixing time compared to older methods. This allows for a greater number of batches to be processed within a given timeframe, leading to substantial gains in productivity.

This enhanced throughput is particularly beneficial in high-volume production environments where even minor reductions in mixing time can have a significant impact on the overall production capacity. The faster turnaround time also contributes to shorter lead times and improved responsiveness to market demands.

Enhanced Scalability and Flexibility

Modern mixing technologies are designed with scalability in mind. This means that the same fundamental principles and design features can be adapted to different production scales, allowing businesses to easily expand their production capacity as needed without requiring a complete overhaul of their mixing infrastructure.

Furthermore, many superior mixing systems offer greater flexibility in handling different types of materials and viscosities. This adaptability reduces the need for multiple, specialized mixing units, streamlining operations and reducing capital expenditure.

In conclusion, adopting superior mixing technology represents a strategic investment for businesses aiming to enhance their production output. The benefits extend beyond increased throughput, encompassing improved product quality, reduced costs, and enhanced operational flexibility – all crucial elements in today's fiercely competitive market.wzwanxi2024-12-30 -

Wholesale Custom Designed Wetsuits Diving Suits Perfect Fit for Men and Women

The allure of the underwater world has captivated humans for centuries. From casual snorkeling to professional deep-sea diving, exploring the ocean's depths requires specialized equipment that prioritizes safety, comfort, and performance. Central to this equipment is the wetsuit – a garment designed to provide thermal protection, buoyancy control, and abrasion resistance in aquatic environments. For businesses looking to supply divers with high-quality, personalized gear, wholesale custom-designed wetsuits represent a lucrative and rewarding venture. These suits offer a unique opportunity to cater to the diverse needs and preferences of both male and female divers, ensuring a perfect fit and optimal performance in any aquatic condition. This detailed exploration will delve into the advantages of offering wholesale custom-designed wetsuits and highlight the crucial factors involved in their successful design and production.Superior Comfort and Performance Through Customization

Standard, off-the-shelf wetsuits often fail to provide the perfect fit for every individual. Variations in body shape, size, and flexibility can lead to uncomfortable pressure points, restricted movement, and compromised thermal insulation. Custom-designed wetsuits, however, address these issues head-on. By taking precise body measurements and considering the diver's specific needs and diving style, manufacturers can create suits that are tailored to their unique physiology. This results in unparalleled comfort, allowing divers to focus on their underwater exploration without the distraction of ill-fitting gear.

Moreover, customized wetsuits enhance performance. A perfectly fitting suit minimizes water ingress, maximizing thermal protection and reducing the need for excessive neoprene thickness. This translates to greater flexibility and agility underwater, allowing for easier maneuvering and more efficient swimming. The ability to customize aspects like seam placement and neoprene panel thickness based on individual body heat distribution further improves both comfort and performance, leading to a superior diving experience.

Materials and Construction: Ensuring Durability and Longevity

The choice of materials is paramount in determining the quality, durability, and performance of a custom-designed wetsuit. High-quality neoprene remains the industry standard for its thermal insulation properties and flexibility. However, the specific type of neoprene, its thickness, and its lining material can be customized to suit various diving environments and individual preferences. For example, divers operating in colder waters might opt for thicker neoprene, while those in warmer climates might prefer a thinner, more flexible option.

Beyond neoprene, the construction techniques employed are critical. Proper stitching, glued and blind-stitched seams, and strategically placed reinforcements are essential to ensure the suit's durability and longevity. Custom-designed wetsuits allow for precise control over these elements, reducing the risk of leaks, tears, and premature wear and tear. The ability to incorporate reinforced panels in high-stress areas further enhances the suit's lifespan, making it a worthwhile investment for serious divers.

Targeting Specific Diving Disciplines and Preferences

The versatility of custom-designed wetsuits extends to accommodating various diving disciplines. Whether it's freediving, scuba diving, spearfishing, or surfing, the design can be tailored to meet the specific requirements of each activity. For freediving, for example, a suit might prioritize hydrodynamic efficiency and minimal drag. For spearfishing, it could incorporate reinforced padding for abrasion resistance and pockets for carrying equipment. This adaptability opens up significant market opportunities for wholesalers, allowing them to cater to a diverse range of customers with specialized needs.

Furthermore, aesthetic preferences can be incorporated into the custom design process. Divers can choose from a wide range of colors, patterns, and customization options, allowing them to express their individuality and create a truly unique wetsuit. This personalization aspect significantly enhances customer satisfaction and builds brand loyalty, creating a positive feedback loop that drives sales and repeat business.

Wholesale Advantages: Maximizing Profitability and Market Reach

Offering wholesale custom-designed wetsuits allows businesses to tap into a lucrative market segment. By purchasing in bulk and offering personalized options, wholesalers can negotiate competitive pricing with manufacturers, ensuring healthy profit margins. Moreover, the ability to offer a wider range of sizes, styles, and customization options broadens the target market and increases sales potential.

Wholesale distribution also facilitates efficient inventory management and reduces storage costs. Instead of maintaining large stocks of ready-made wetsuits in various sizes, wholesalers can focus on managing orders and coordinating production with manufacturers. This streamlined approach minimizes warehousing expenses and reduces the risk of inventory obsolescence.

In conclusion, wholesale custom-designed wetsuits represent a compelling business opportunity. By focusing on superior comfort, performance, durability, and personalized options, businesses can capture a significant share of the diving equipment market. The ability to cater to diverse diving disciplines and individual preferences through customized designs ensures customer satisfaction and fosters brand loyalty, driving sustained growth and profitability in this niche market.

dgruisha2024-12-27 -

Wholesale Yoga Pants Leggings and Bras Custom Designs Available for Your Brand

The fitness apparel market is booming, with consumers increasingly seeking high-quality, stylish, and comfortable activewear. This presents a significant opportunity for entrepreneurs and established brands alike. But navigating the complexities of manufacturing, sourcing materials, and managing inventory can be daunting. This is where wholesale yoga pants, leggings, and bras, with custom design options, come in. Offering a streamlined path to market, this approach allows you to focus on branding and marketing while leveraging the expertise of experienced manufacturers to produce top-notch products. This article explores the benefits and considerations of offering your brand's unique style through wholesale yoga pants, leggings, and bras with custom design capabilities.Unleashing Your Brand's Unique Style Through Custom Designs

One of the most compelling aspects of wholesale activewear is the ability to create completely unique designs tailored to your brand's identity. This allows you to differentiate yourself from competitors and establish a strong visual presence in the market. Imagine leggings adorned with your logo, incorporating your brand's signature colors and patterns, or featuring original artwork reflecting your brand's values and aesthetic. This level of customization extends beyond simple logos; it encompasses fabric choices, stitching styles, waistband designs, and even the addition of unique functional features.

The creative freedom offered by custom design opens doors to telling a story through your apparel. You can collaborate with artists, incorporate sustainable materials, or create limited-edition designs to engage your target audience on a deeper level. This personalized approach fosters brand loyalty and creates a sense of exclusivity, building a community around your products that transcends mere transactions.

Furthermore, custom designs allow you to cater specifically to your target demographic. Are you aiming for a sophisticated, minimalist aesthetic? Or perhaps a bold, vibrant, and energetic look? Custom designs allow you to perfectly align your apparel with your brand's target audience, ensuring maximum impact and relevance.

High-Quality Materials and Manufacturing for Lasting Impressions

Choosing a reliable wholesale supplier is crucial to the success of your brand. A reputable supplier will offer a wide range of high-quality materials, ensuring your yoga pants, leggings, and bras are both comfortable and durable. Consider factors like fabric weight, breathability, moisture-wicking capabilities, and overall feel. Opting for premium materials directly reflects on the quality of your brand and enhances the customer experience.

Beyond materials, the manufacturing process itself is critical. Look for suppliers who prioritize ethical and sustainable manufacturing practices. This not only aligns with growing consumer demand for responsible sourcing but also protects your brand's reputation. Transparent and ethical supply chains build trust with your customers, fostering a positive brand image.

Finally, working with experienced manufacturers often translates to superior quality control. A skilled manufacturer will ensure consistent product quality, minimizing defects and returns. This saves you time, resources, and potentially significant financial losses associated with damaged or flawed products.

Cost-Effectiveness and Scalability for Growing Your Business

Wholesale sourcing provides a significantly more cost-effective approach compared to in-house manufacturing, particularly for startups and smaller businesses. By eliminating the overhead associated with setting up and managing your own production facility, you can allocate resources more strategically to marketing, branding, and customer acquisition.

Moreover, wholesale partnerships offer scalability. As your brand grows, you can easily increase your order volume to meet the rising demand, ensuring you can fulfill orders promptly and maintain customer satisfaction. This flexible production model allows your business to adapt to market fluctuations and seasonal changes without significant logistical challenges.

The cost savings achieved through wholesale sourcing can also be reinvested into marketing initiatives, enhancing your brand's visibility and reach. This creates a virtuous cycle of growth, where efficient production translates into increased marketing efforts, leading to greater sales and further expansion.

Building Your Brand Story Through Collaboration and Support

Working with a reputable wholesale supplier is about more than just sourcing products; it's about forging a partnership. A good supplier will provide expert guidance throughout the design and production process, offering valuable insights and support. This collaborative approach allows you to leverage their expertise, ensuring your vision is translated into high-quality, marketable products.

Many wholesale suppliers offer comprehensive services beyond manufacturing, including design assistance, sampling, and quality control. This streamlined approach minimizes the burden on your team, allowing you to focus on the strategic aspects of your business – building your brand, marketing your products, and engaging your customer base.

This collaborative relationship often extends beyond the initial order. A strong supplier will provide ongoing support, addressing any questions or concerns you may have, ensuring a seamless and productive working relationship. This level of support is invaluable, particularly for businesses navigating the complexities of the fitness apparel market for the first time.

Conclusion: The Path to a Successful Activewear Brand

Wholesale yoga pants, leggings, and bras with custom design options provide a compelling pathway to success in the competitive fitness apparel market. By leveraging the expertise of reliable suppliers, focusing on high-quality materials, and creating unique designs that reflect your brand's identity, you can establish a strong brand presence, build customer loyalty, and achieve sustainable growth. The opportunity to create truly unique and high-quality apparel allows you to focus on what you do best: building your brand and connecting with your customers.

dgruisha2025-01-02